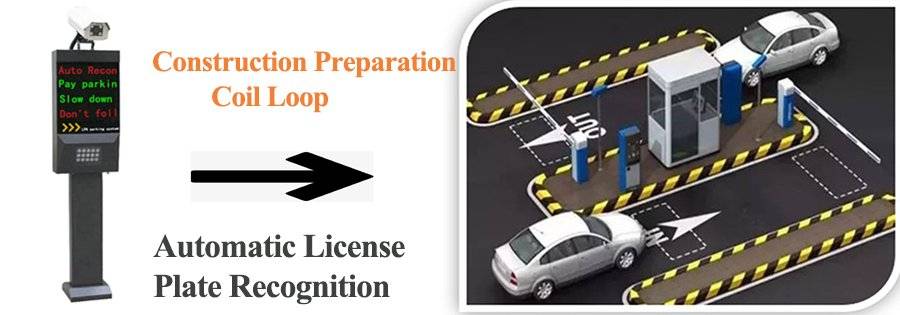

1.Before construction of the coil loop, the position, size and number of circles

shall be confirmed according to the overall wiring arrangement of the project.

The number of circles determine the inductance of the entire coil between 100-200 (UHF), and 150-180 (UHF) is recommended to ensure the perfect working range of the vehicle detector.

2. The coil loop must not damage the protective layer. Use a digital meter to measure the resistance to ground is greater than or equal to 10MΩ, and the DC resistance is 4-6Ω.

3. Within 50 cm of the surrounding area, there should be no large amounts of metal, such as manhole covers, rain gutter covers, etc.

4. There must not have the power supply lines of 220V within 1 meter.

5. When making multiple coils, the distance between the coils should be greater than 2 meters, and the number of circles should not be equal to each other, otherwise they will interfere with each other.

6. Make 45-degree chamfers on the four corners and smooth them to prevent sharp corners from damaging the coil cable.

7. The cable length should be calculated in advance and sufficient margin should be reserved (including the coil lead-out wire). No intermediate joint is allowed in the middle of the coil laying ,cables must not be broken. The wiring should be placed at the bottom of the slot as much as possible, and the cables should be arranged in an orderly manner and should not cross or overlap.

8. The lead wire from the coil to the vehicle detector should be twisted for more than 20 cycles/m, and the distance between the lead wire and the vehicle detector should be as short as possible (if the distance is too long, the ground sensitivity will be reduced), It is recommended that the distance be within 1 meter, and the maximum should not exceed 5 meters.

Further explanation link: https://www.loyalty-secutech.com/anpr-and-alpr-camera/

Shenzhen Loyalty-Secu Technology Co., LTD